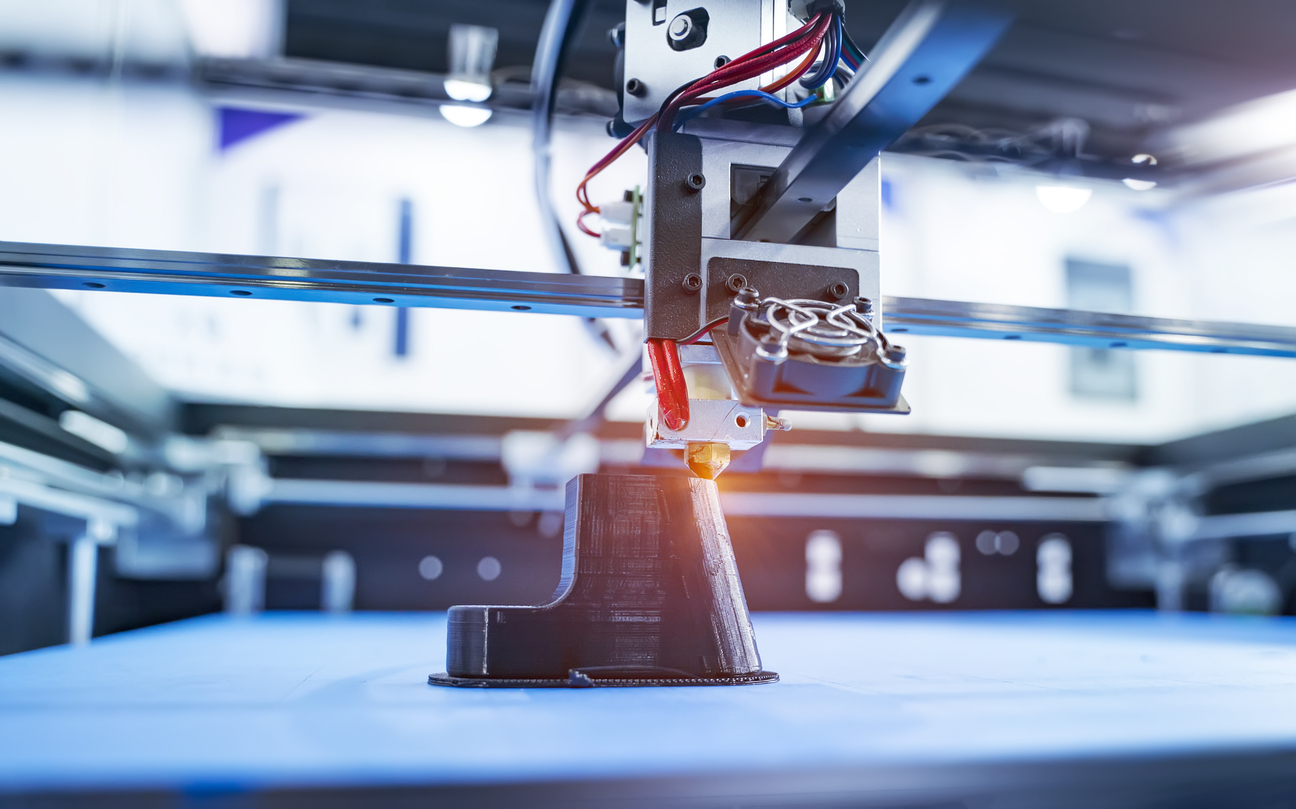

Plastic part prototype

At NOCENTE, plastic prototyping is an essential step in developing parts intended for injection molding. It allows creating unique or small series prototypes to validate the concept, perform various tests and validations, and produce pre-series for marketing, product launch, or substitution series purposes. This approach offers the flexibility needed to make quick and economical adjustments compared to the industrialization phase.

To meet our clients’ specific needs, we offer a wide range of rapid plastic prototyping technologies, including 3D printing, stereolithography, CNC machining, vacuum casting, and the development of prototype molds for plastic injection. These methods provide reduced production times and optimized manufacturing costs compared to mass production. Using your CAD models, typically in 3D format (.STEP or .IGS), our engineering office designs the prototypes with precision.

Plastic prototyping offers numerous advantages, including visual, functional, and mechanical validation of parts. It allows testing different versions, materials, and finishes, as well as verifying the shape, aesthetics, and mechanical performance of the parts. Additionally, it enables assembly tests to identify potential design errors and ensure the overall functionality of the assembly.

Regarding the prototype mold for small series plastic injection, NOCENTE has developed a specific solution adapted to producing small series and pre-series (quantity of 100 to 1000+ pieces). This intermediate method between rapid prototyping and series production involves using a prototype mold in an interchangeable cavity frame. While requiring a higher initial investment and longer fabrication times than rapid prototyping, this method offers parts with robustness and mechanical properties equivalent to series production. For even smaller series (less than 200 pieces), vacuum casting technology can be recommended, also allowing insert overmolding.

Plastic part design

The design of molded plastic parts by injection is a complex process that requires considering several aspects to ensure the quality, functionality, and manufacturability of the parts.

Learn moreInjection mold design

Tooling Design in the NOCENTE engineering office is our core business and the fundamental step in the industrial manufacturing process of plastic parts

Learn more