Plastic part design

The design of molded plastic parts by injection is a complex process that requires considering several aspects to ensure the quality, functionality, and manufacturability of the parts. Before starting the actual design, it is essential to define the client’s needs and the specifications of the plastic part to be designed. This includes understanding functional requirements, manufacturing constraints, aesthetic criteria, and industry standards. Sketches, drawings, and conceptual models are created to explore different design options and assess their feasibility.

Basic Rules to Consider When Designing Plastic Parts for Injection Molding:

1. Continue Thickness:

Maintain uniform wall thickness to ensure even cooling and avoid internal stresses that can cause deformation. A wall that is too thick increases the risk of shrinkage and significantly prolongs the production cycle time. Generally, main thermoplastics work for functional parts between 1.5 and 3.5 mm.

2. Avoid Sharp Corners and Edges:

Round corners and edges to reduce molding stresses and avoid stress concentration areas that could lead to cracks or poor material flow distribution.

3. Add Draft Angles:

Draft angles are inclines or slopes added to the part walls to facilitate its ejection from the mold after the molding process.

- Draft Angle: The draft angle is determined by the slope of the part walls relative to the direction of ejection. A typical draft angle generally varies between 0.5° and 3° but can be adjusted based on the part's geometry and molding process requirements.

- Uniformity: Draft angles should be uniform on all part walls to ensure good ejection. Variations in angle can lead to ejection issues and surface defects on the molded part.

- Positioning: Draft angles should be strategically positioned to ensure smooth ejection of the part while minimizing interferences with other mold components or the part itself.

Undercuts:

Undercuts are cuts or recesses added to the part to create complex features or internal details. Unlike drafts, undercuts often require the use of moving parts or special inserts in the mold.

- Mold Design: Undercuts can complicate the mold design by requiring the use of moving parts or adding extra steps to the molding process.

- Interferences: Undercuts can cause interference issues with other mold or part components, especially during ejection.

- Potential Defects: Undercuts can also lead to molding defects such as flow marks or weld lines if not properly designed or positioned.

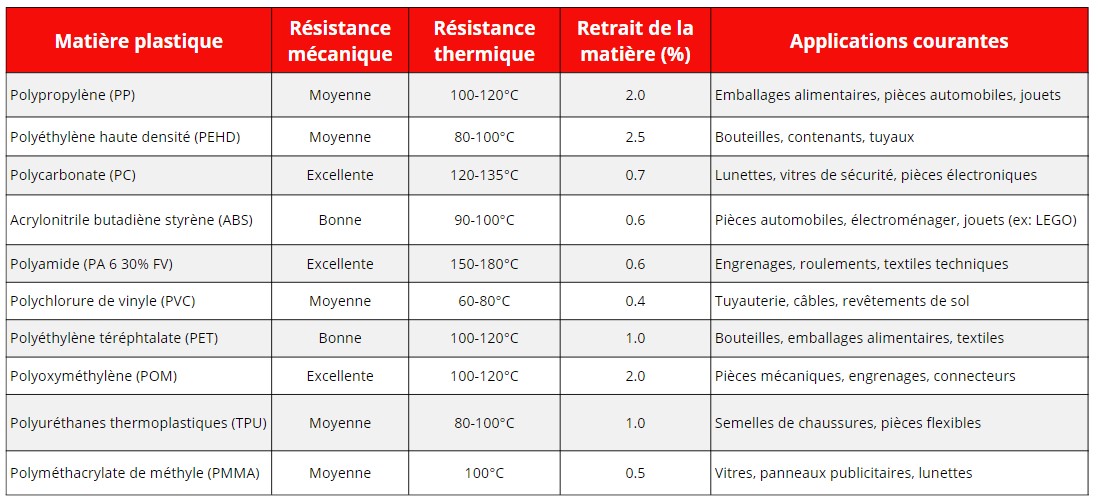

4. Plastic Material Selection:

Consider the plastic material’s shrinkage during cooling by adjusting the part dimensions accordingly to achieve the desired final dimensions. Choose a plastic material suitable for the part’s functional requirements, considering factors like mechanical strength, chemical resistance, operating temperature, and aesthetic properties.

5. Validation and Approval:

Before proceeding to the manufacturing phase, the plastic part design undergoes thorough validation to ensure it meets all functional, aesthetic, and safety requirements. Physical prototypes may be developed for field tests and final evaluations.

Injection mold design

Tooling Design in the NOCENTE engineering office is our core business and the fundamental step in the industrial manufacturing process of plastic parts

Learn morePlastic part prototype

At NOCENTE, plastic prototyping is an essential step in developing parts intended for injection molding. It allows creating unique or small series prototypes to validate the concept

Learn more