- Modifications required by product evolution

On molds manufactured by Nocente or third-party molds - Repairs

On molds manufactured by Nocente or third-party molds

Plastic injection mold design

Our

offer

Project

Maintenance

1. Design & conception

Assist product development

Part

2D & 3D modeling of parts

Rapid prototyping of parts

Rapid prototyping of parts

- Assistance in defining and optimizing your plastic parts

- Rheology study and choice of plastic materials

- Moldflow study

MOLD to produce the part

MOLD to produce the part

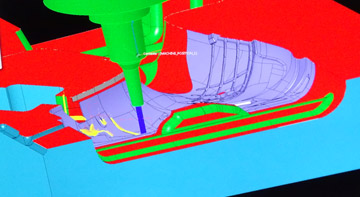

Modeling the mold

Product testing

- Kinematic study of the mold including optimization of feeding, cooling, ejection and speed.

- 2D plan validation

2. Manufacturing

Computer-Assisted Manufacturing

Nocente has chosen partners to offer the best value for money for quality tooling.

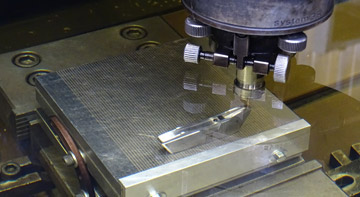

Finishing at Voiron

Nocente takes full responsibility for the project

- Mold study carried out at the Voiron site

- Supervision of manufacturing

- Analysis and supply of sample parts

- Inspection of the mold in our workshop before delivery

- Modifications and final adjustments in our workshop

Tooling is therefore produced to the design and standards usually performed by Nocente.

- Wax injection testing

Surface finishing

- Polyglass

- Chemical grinding or laser engraving

- Sandblasting

- Polishing

Transfer

3. Final stages

Supply of the first parts (samples)

Transfer of injection parameters